NuShine® IIG6

Graded system of polishing compounds for clad, cast or forged aluminum, nickel, stainless steel & other metal surfaces that are brand new, oxidized with use, or with atmospheric corrosion. When using any NUVITE product, please refer to appropriate procedures and recommendations for use and equipment, or contact a NUVITE technician for more information, unique applications and special requirements.

NuShine® IIS

NuShine® IIA

NuShine® IIC

NuShine® IIG6

NuShine® IIF7

NuShine® IIF9

NuShine® IIF10

Final, Mirror Finish

Repolish & Light Touch Up

Oxidation Removal & Repolish

Oxidation Removal & New Metal

Heavy Oxidation & Scratch Repair

Heavy Corrosion & Surface Repair

Titanium & Select Metals

NUSHINE II is a metal polishing system that addresses varying surface conditions. So while procedural steps may be the same, the condition of your surface will dictate the grade with which you begin and the number of steps that will be required.

For example, lightly pitted, very dull metal or new, clad aluminum may require NUSHINE® IIF7 to start. Polished metal with moderate to severe cloudiness and small surface scratches can be brought back to shine with NUSHINE® IIC or NUSHINE® IIG6.

If you’re undecided where to start or how to move on, ask a NUVITE technician. Our job is to help you shine!

When using any NUVITE product, please refer to appropriate procedures and recommendations for use and equipment, or contact a NUVITE technician for more information, unique applications and special requirements.

Before beginning a polishing job ANY oils, paraffin (from smoke oils) and dirt must be removed from the surface. For best results the surface should be dry and there should be normal humidity conditions.

1. Begin with a new or clean wool compounding pad on a circular / rotary type buffer.

2. Wet a clean bristle, 1” paint brush (alternatively, you can use one finger), with a dab (1/4 – ½ teaspoon) of NUSHINE® II.

3. Smear the dab of NUSHINE® II approximately 1 1/2 “ long or about half a finger length, every 3”, over an 18”-24” target polish area*

4. Spread quickly, DO NOT allow the polish to dry.

5. Place the clean wool compounding pad on the smear area and further smear area the polish a little before turning on the buffer. We recommend running buffer around 2000 RPM.

6. DO NOT LAY BUFFER PAD FLAT AGAINST POLISHING SURFACE. Tilt the pad up 10-15 degrees. Only one side of the pad should touch the surface as it spins. This helps pinpoint a specific, target polish area.

7. With pad tilted up 10-15 degrees, move buffer over the surface at a speed of about 1-2 seconds per foot as it spins.

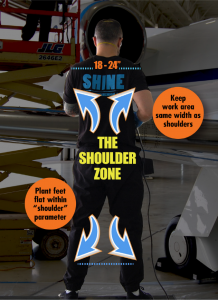

8. THE SHOULDER ZONE: Beginning top right or left of target polish area*, work back and forth to bottom of the target polish area. Then work same area up and down.

9. Light, but firm pressure is all that’s needed. DO NOT PRESS HARD AGAINST THE SURFACE.

10. On horizontal surfaces, pressure should be about the weight of the buffer.

11. Black residue will form over the 18”-24” target polish area. Continue moving the buffer back and forth/up and down across the surface for about 30-45 seconds. The black residue will begin to lighten and disappear.

12. Keep moving over the target polish area until black residue is gone and the clean aluminum surface shows.

Black residue may remain around the edges of the buffed area, but will be cleared as adjoining areas are buffed.

13. If there is cloudiness or scratches remain, repeat above steps until the surface is clear.

14. Repeat the above steps with each adjoining area.

15. When the wool compounding pad looks shiny with polish, fluff the nap by “spurring” with a buffing spur or a screwdriver blade held vertical against the face of the spinning pad.

FOR FINAL FINISH: With NUSHINE® IIS before starting, use a dry, clean microfiber cloth to hand wipe the surface clean of the cutting grade polish.

1. Wrap cotton flannel polishing cloth over the face of the random orbital (dual head) buffer’s foam pads.

2. Check that any motor air vent openings are unobstructed.

3. Wet a clean bristle, 1” paint brush (alternatively, you can use one finger), with a dab (¼ – ½ teaspoon) of NUSHINE® IIS.

4. Smear the dab of NUSHINE® IIS app 1 ½” long or about half a finger length, every 6” over an 18”-24” target polish area*.

NOTE: This is half the amount of polish used with other NuShine® II grades.

5. Spread quickly, do not allow the polish to dry.

6. Pull cotton flannel polishing cloth tightly over the face of the buffer. Hold flannel with your hand as you grip the buffer handle.

7. Smear the face of the buffer around the area to be polished before turning buffer on.

8. Move buffer over the surface area at a speed of about 3 seconds per foot as it spins. Use only light pressure.

9. THE SHOULDER ZONE: Beginning top right or left of target polish area*, work back & forth, right to left within the targeted polish area. Then work same area up and down.

10. In the target polish area, work the buffer AROUND raised rivets and seams so as not to file them down.

11. The buffing pad can be tipped a small amount around raised rivets and panel lines to reach polish.

12. Black residue will appear as before and begin to lighten and disappear after about 30-45 seconds. If not, too much polish may have been applied.

13. Keep moving over the target polish area until bright, shine appears.

14. Work back over rivets and panel lines to clean residue from those areas.

15. When designated area is clean of surface polish, stop the buffer and move/recycle the flannel to a new, clean spot of the material.

16. Final buff over the whole area.

17. Final finish with clean flannel polishing cloth by hand, lightly cleaning close in around rivet heads and with folded material to get against the edges of the seams.

QUESTIONS? NUVITE technicians have the answers 800.394.8351

Keep in mind: When using any NUVITE product, please refer to appropriate procedures and recommendations for use and equipment, or contact a NUVITE technician for more information, unique applications and special requirements. *Product dilution where applicable is determined by extent, condition & soil type.

© Nuvite Chemical Compounds 2024 | All Right Reserved. |

© Nuvite Chemical Compounds 2024 | All Right Reserved. |